Innovation and efficiency through aluminum pressure casting

Alucast is a part of the Rubitech group of companies. The basis of Rubitechs product offering is aluminium, focusing on high pressure die casting. Gas tight appliances, heat exchangers and coated esthetical products is our specialism.

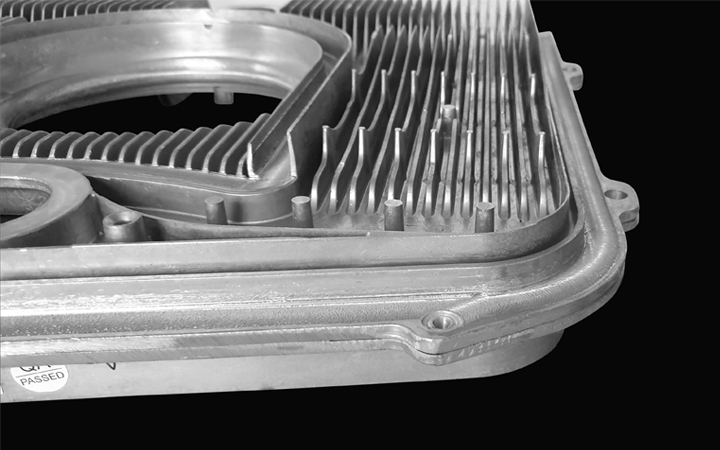

Our aluminum die casting production process is characterized by precision and superior quality. Meticulous, we use state-of-the-art technologies to produce components for a wide range of applications: lighting, furniture, kitchen accessories, industrial equipment.

Customized components

Whether our customers want to invest in complete new product designs or want their finished design to be produced, they call on Rubitech Alucast to deliver products to meet their unique requirements.

Diecasting is an essential process for obtaining quality parts. Rubitech Alucast uses modern machining methods, such as CNC milling, drilling and waterjet cutting, to ensure the precision of geometries and tolerances imposed by customer specifications.

Rubitech Alucast specializes in the production of aluminum components by high pressure die casting. This production method allows complex parts with precise geometry to be made at a high production rate.

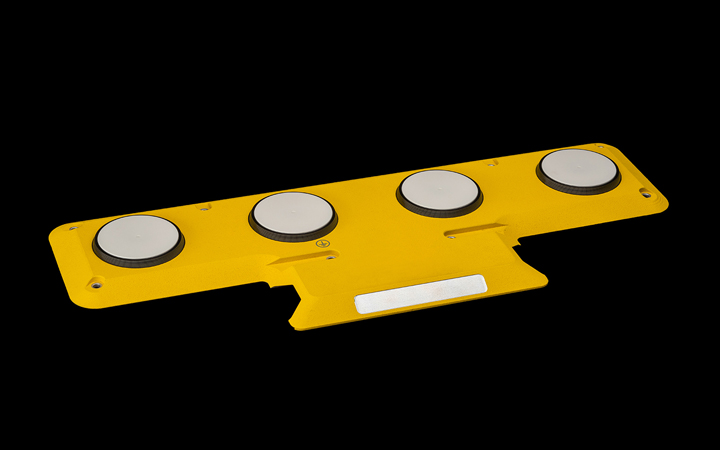

To provide high quality products, we apply powder coating techniques to die cast parts. This coating process consists of applying an electrostatic powder which is then heated in an oven. The end result is a uniform coating with increased durability, which gives our parts an aesthetic appearance and additional protection against environmental factors.

Also, the machining of die-cast parts is an essential process for obtaining quality parts. Rubitech Alucast uses modern machining methods, such as CNC milling, drilling and waterjet cutting, to ensure the precision of geometries and tolerances imposed by customer specifications.

One of our areas of expertise is the production of die-cast kitchen parts. We use high-quality aluminum and precision die-casting methods to make products that meet the most demanding quality and performance requirements.

Diecast surface quality is an important feature of our products. We use advanced die casting technologies and carefully monitor the manufacturing process to ensure a smooth and uniform finished surface. By applying powder coatings, we manage to offer additional protection and a special aesthetic appearance.

Main markets: Benelux, Germany, France, Slovenia, UK and Scandinavia. Competitive cost positioning of our aluminum die casting solutions and mid to high end LED products resulting in a value proposition for our customers Rubitech is known for its solution oriented approach in the areas of engineering, manufacturing, supply chain management and logistics.

Our technologies

Casting

Aluminium high pressure die castings starting from 20g up till 6kg.

Machining

CNC machining up to 12um.

Surface treatment

Powder coating. ED coating. Anodizing. Passivation. Tumbling. Sand blasting.

Friction stir welding

High integrity and reliable welds in aluminium die castings.

Assembly

Assembly of kit parts on to an aluminium die casting.

Prototyping

Protypes machined out of solid alumium or 3D printed.

Global solutions

Die casting Dutch management

Rubitech Alucast is a global company with headquarters in the Netherlands and production facilities in Malaysia and Romania. This broad geographic presence enables us to provide customized solutions worldwide, meeting the unique requirements of our clients.

Die Casting Romania

Die Casting Malaysia

We take care of your unique requirements

We have developed and produced more than 1000 customized products. How can we help you?

Our services

Design & Development

The product design and development phase presents several hurdles before the final product rolls off the production line, especially if your experience in working with aluminium die casting is limited. Rubitech Alucast’s Design & Development solutions are there to help designers and engineers ensure their product designs overcome any production obstacles that stand in their way. With more than 1,000 different component projects in our portfolio, we understand your challenge.

Production & Assembly

A thorough understanding of technical advancements enables us to create and apply technical innovations for cost-effective series production and to alleviate risk during production. Moreover, it yields opportunities to cast several components as a single unit, simplifying your supply chain and allowing you to stand out in the market.

Supply Chain Solution

Rubitech offers customer-centric supply chain solutions. The whole logistics process is adjusted to suit your demands and wishes, whether you want your products to be delivered directly to your warehouse or production facility or you prefer Rubitech to coordinate transport and stock control.

“We deliver die cast aluminium components on the highest level. 30 years in business taught us a lot. We made and delivered more than a 1000 unique dies. Mid-size volumes for the non-automotive market is our speciality. Always using automotive standards.”

“Often we get asked if it’s possible to make a challenging product. Only quality engineered products that are guaranteed to be the best, we make and deliver, inventive and fast – a statement we take incredibly seriously.”

Ronald Booij – commercial manager